Your basic tools: Electric Drill ( Nothing Fancy)

80, 120, 180, 220, 320,400 grit Wet/Dry Sandpaper

(2) 6" Spiral Sewn Buffing Wheels

Tripoli Compound

White Rouge

These parts can be found at Home Depot, Sears, and some major Auto Chains

Optional Items Tapered Sanding Rolls 80-320 grit w/ mandrel

(1) 6" Ventilated Flap Buff Wheel

Assorted Mini Buffs w/ mandrel

Assorted Buffing Bobs

(1) Buff Rake

Safety Equipment: Safety Glasses or Face Shield, Disposable Dust Mask or Respirator, Gloves, Padded Clamps or Padded

Vice to hold the smaller parts with ( otherwise they will fly ) while Buffing or Polishing.

The Basic items you you can purchase from the stores mentioned above. I bought the Eastwood Aluminum Polishing Manifold Kit # 13149 ($49.99) which gives you everything you need to do your upper and lower manifold with and other aluminum pieces if you choose to .

POWDER COATING: (REMOVAL)

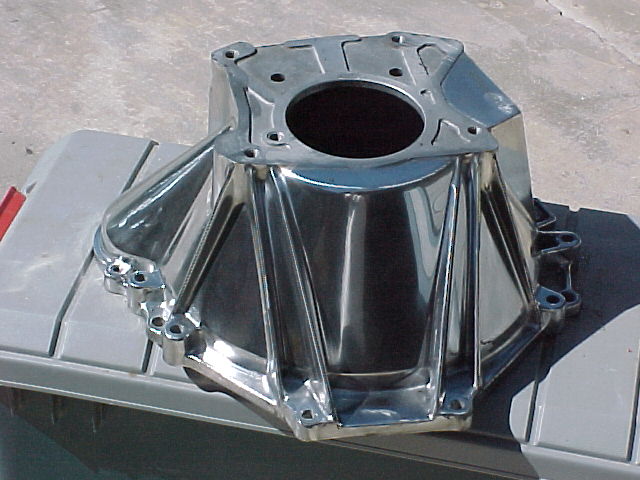

To polish the upper intake you first need to remove the powder coating , this can be done by 2 methods . First method is you could sand the powder coating off which will take for ever or the second method is you can use Air Plane Paint Stripper ( not regular paint stripper ) which only takes 20 min - 45 min depending on the manufacture, whatever you do follow the instructions on the can this stuff is toxic and will burn your skin. You can find the Air Plane Paint Stripper at most local automotive paint stores or at some of the larger automotive chain stores, Auto Zone, Kragens, Pep Boys Chiefs, etc.

I personally would not suggest using a wire wheel or sand blasting to remove the powder coating these methods only leave deeper scratches or pits that you'll have to sand out later.

SANDING: (80-400 grit)

Now that the powder coating has been removed you need to start the sanding process . 1st start with 80 grit sand paper to remove all the rough casting form the piece, the big flat areas are not a problem it's the smaller areas that are the problems this is why I suggested Tapered sanding rolls which will help speed up the process of sanding, but it can be done by hand sanding.

Now that you have the whole piece sanded with 80 grit you now need to use the 120 grit sand paper to remove the scratches that the 80 grit sanding left, next you need to use the 180 grit sand paper to remove the sanding marks left by the 120 grit sand paper . You'll need to repeat this process using the 220-400 grit sand paper. I never sanded any of the pieces I did with more than 320 grit. I have read where some people have even sanded with 600 &1000 grit, that's just to much sanding for me by the time you have sanded with 80, 120, 180, 220, 320 your tired of sanding, let the Tripoli Buffing Compound take the fine. sanding marks out.

BUFFING: (Tripoli Compound)

Tripoli Compound : is used for general cutting of all non-ferrous metals ( aluminum, brass, etc. ) Mild cutting action best used with either spiral sewn or ventilated flap buff wheel. This compound comes either in a stick or tube, reddish in color.

Buffing or Polishing can be done with a cheap electric drill ( $ 10- $40 ) or a Baldor Buffing motor ($ 200 - $500)

The basic principle of buffing is to remove any of the fine sanding marks left after sanding .

To buff you need to have the piece secured to the work area in some form ( padded clamped, bolted or padded vice ) or when you start to use the wheel on the item you will probably catch an edge or something and the item will hit the ground either braking it ( which happened to me ) or putting a big dent in the piece that you can't get out !

After you have the piece secured put a 6" spiral buffing wheel in your electric drill and with medium pressure run the wheel over the Tripoli compound, apply a small amount of the Tripoli to the wheel , with the Tripoli on the wheel apply slight to medium pressure to the piece your buffing. If you try to apply to much pressure to the piece the Tripoli will only clog up and leave black marks, and will not do the work it was intended for. Buff out a small area at a time using a left to right motion do not use a circular motion , apply compound as needed, smaller amounts of compound are easier to work with than one large amount , after you have the entire area buffed move on to another area using the same procedure, by this time you will start to see a nice shine come to the piece, your almost there.

I suggest for the smaller areas use smaller buffing wheels ( mini buffs) to get into those hard to reach places.

POLISHING: (White Rouge Compound)

White Rouge Compound : is primarily a coloring compound to produce a brilliant mirror like finish. For all metals. This is

final step before plating. Use loose section ,canton flannel or spiral sewn buffing wheel.

This is the final step to that mirror like finish your looking for.

Again make sure the item is secured to the work area, using another ( different) 6" spiral buffing wheel, do not use the same 6" spiral sewn buff that you used with the Tripoli as this buffing wheel is contaminated with the Tripoli and will not let the White Rouge work properly. Using the same procedure as buffing when applying the the White Rouge to the wheel ( slight to moderate pressure) again start in a small area and working into a larger area, applying compound as needed , use a small amount of compound at a time. Work from left to right or right to left just try to stay from any circular motions if possible.

Your piece is now finished to a mirror like finished something to be proud of after all the hours you've spent.

One final thing if at any point you see a deep scratch from sanding you may have missed while your buffing just go back and touch up that area with sand paper to remove the sanding mark.

All you really need is time and patience's

For those who are wondering how many hours it take to do the upper intake my best guess would be some where between 12- 16 hr. I never kept track of the time.

By: Paul

|